Introducing, the Dinghaode Multi-Layer Construction Board Wood Formwork, a reliable and durable solution designed specifically for concrete formwork projects. This product is made to help builders and contractors achieve strong, precise, and efficient concrete structures with ease.

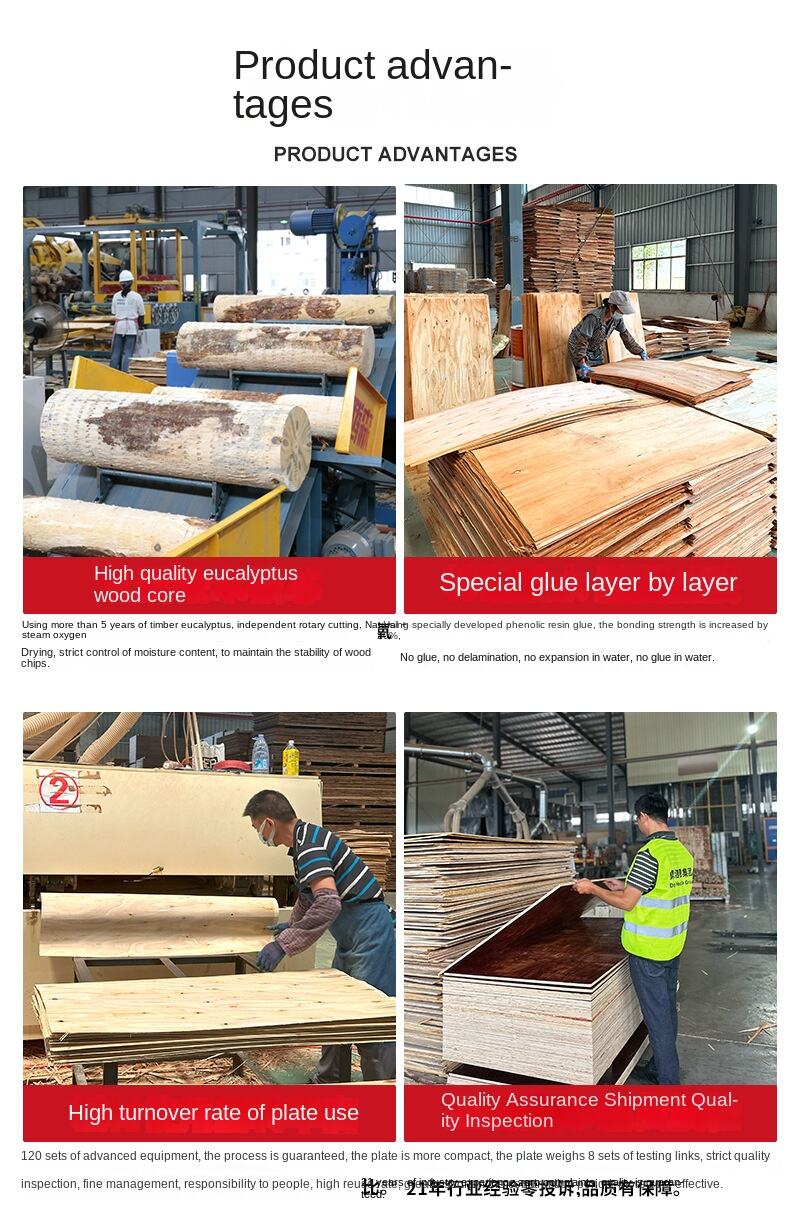

The Dinghaode formwork board features a multi-layer construction that combines strength and flexibility. Each layer of wood is carefully bonded together to create a full whole core that provides excellent support and stability. This robust core helps prevent bending or breaking during use, ensuring your concrete forms stay secure throughout the construction process.

One of the key advantages of this board is its outstanding corrosion resistance. Unlike traditional wooden formwork that can suffer from water damage or rotting over time, Dinghaode’s special treatment and high-quality materials make this board resistant to moisture, chemicals, and other harsh conditions commonly found on construction sites. This means fewer replacements and repairs, saving both time and money.

The design also features an interlocking system that makes assembling and disassembling the formwork quick and hassle-free. The boards fit together tightly, creating strong joints that maintain the form’s shape and prevent leaks or gaps where concrete could escape. This interlocking feature improves work efficiency and contributes to a neater, more precise finished product.

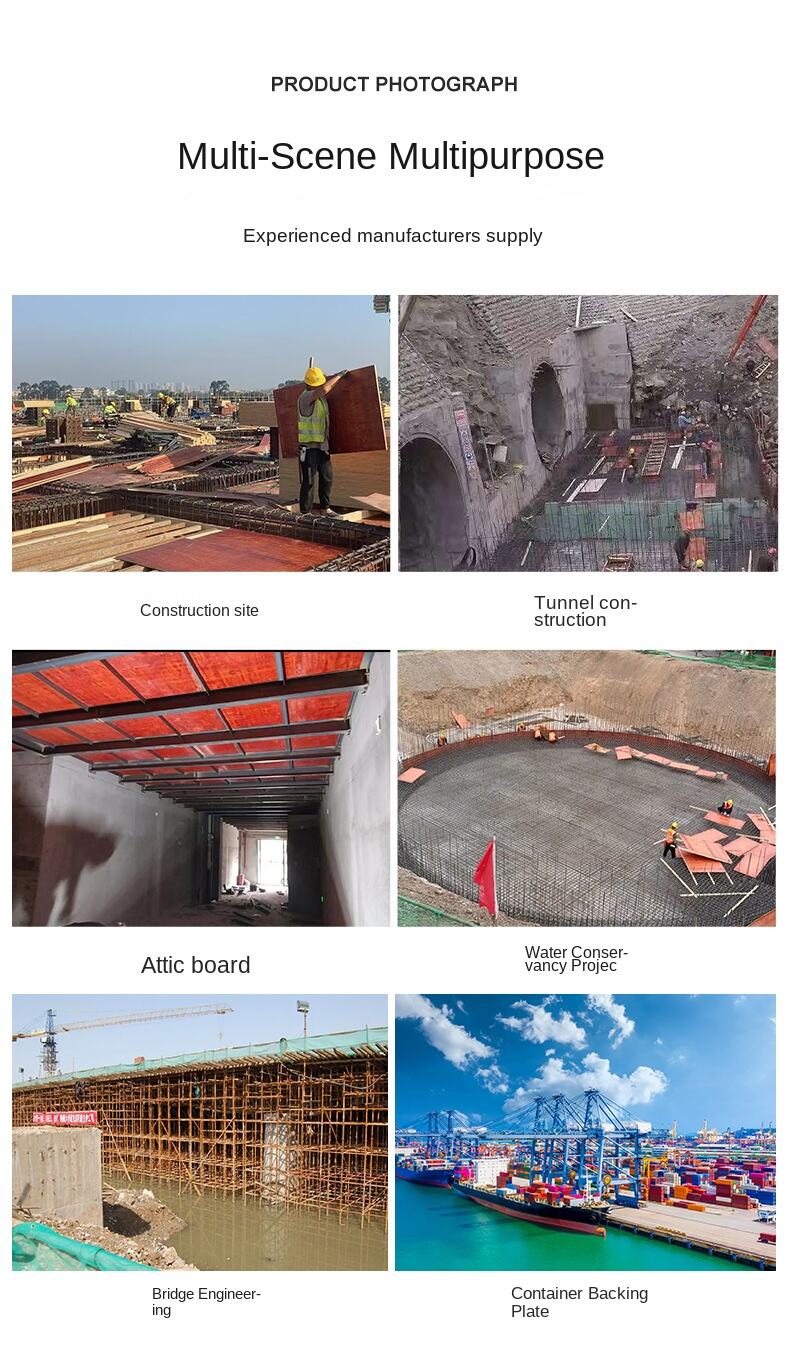

Dinghaode’s Multi-Layer Construction Board is incredibly versatile. It suits a wide range of concrete projects, from foundations and walls to columns and slabs. Whether you are working on a small residential build or a large commercial site, this formwork board adapts to your needs and delivers consistent, high-quality results.

In addition to its strength and durability, this product is lightweight compared to traditional solid wood boards, making it easier to handle and transport on-site. The smooth surface of the board also allows for easy cleaning and reuse, further enhancing its cost-effectiveness.

The Dinghaode Multi-Layer Construction Board Wood Formwork is a top choice for those seeking a sturdy, corrosion-resistant, and easy-to-use solution for concrete formwork. Its full whole core, interlocking design, and durable materials ensure your construction projects will progress smoothly and produce excellent outcomes every time. Choose Dinghaode for dependable formwork that stands up to the demands of modern building

| item | value |

| Project Solution Capability | Others |

| Application | Other |

| Design Style | Modern |

| Material | Other |

| Feature | Other |

| After-sale Service | Other |

| Place of Origin | China |

| Warranty | 1 Year |

| Installation | interlocking |

| Surface Treatment | Brushed |

| Surface | Embossed |

| Brand Name | Taurus |

| Model Number | F005 |

| Nominal Product Length (ft.) | 1.0-2.0cm thick |

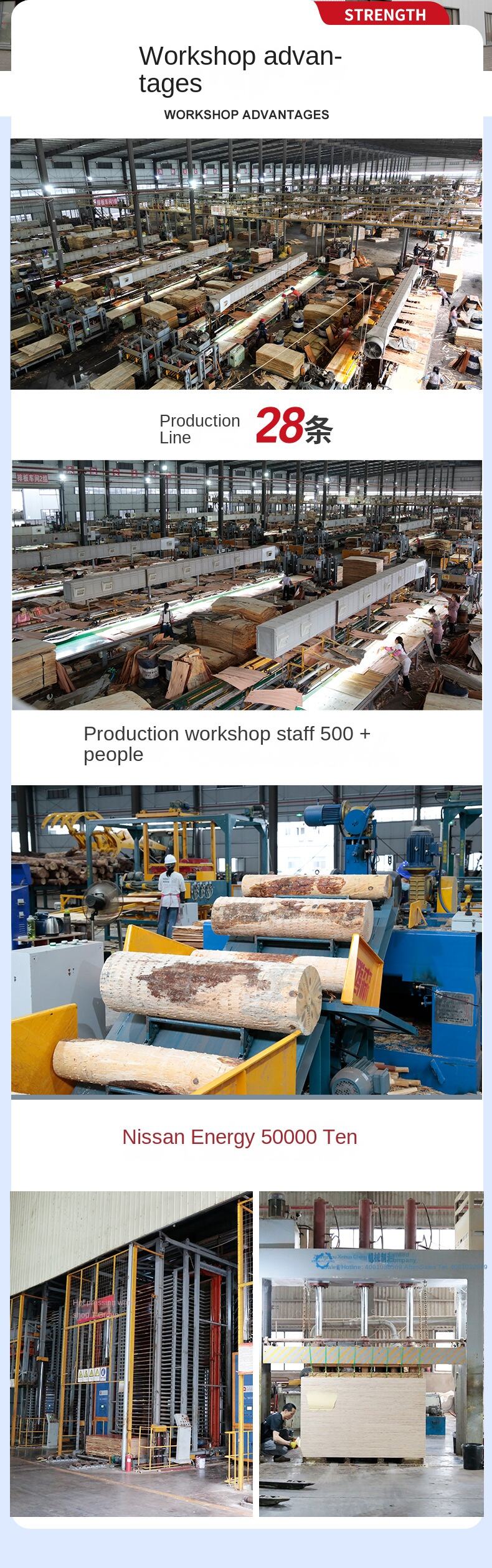

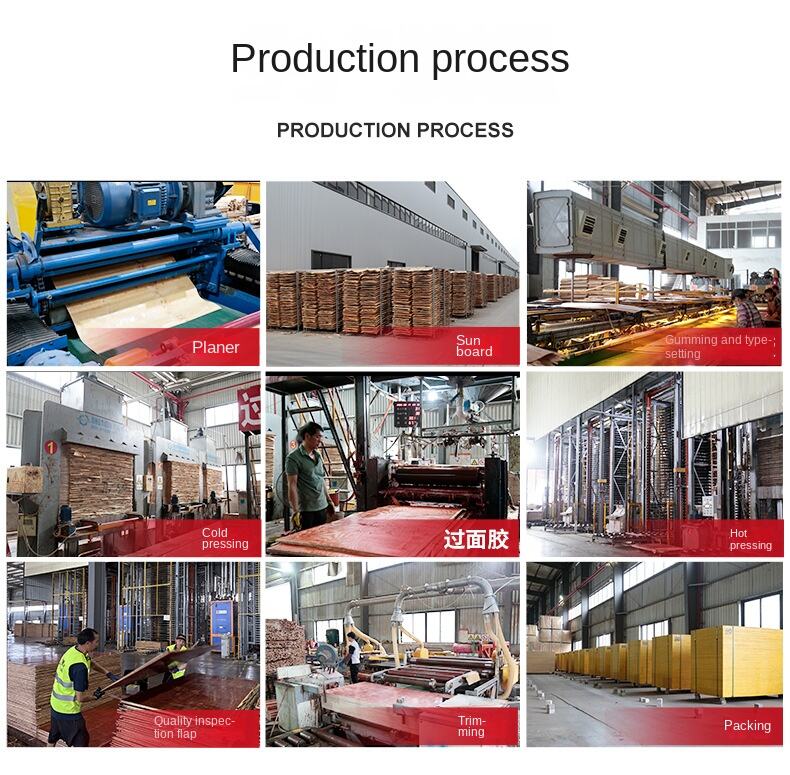

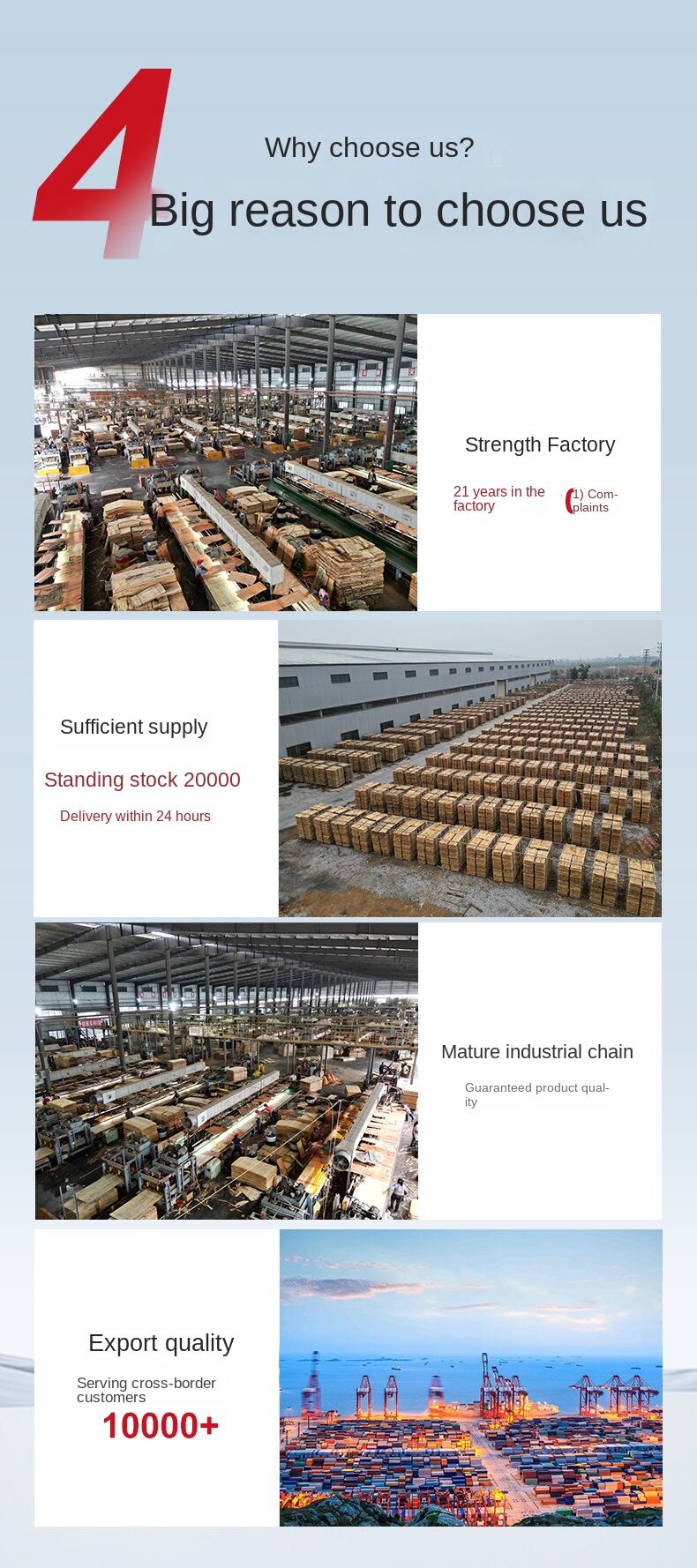

Guangxi Dinghaode Wood Industry Co., Ltd. has its production base located in the Guiping Ecological Industrial Park, Guangxi. The company covers an area of 188 mu and has over 500 employees. It mainly produces construction wood formwork. The company is equipped with advanced automated production facilities and has a daily output of over 80,000 sheets. 2. The finished sheet products not only ensure smoothness and flatness but also possess strong tensile strength and water resistance, with the advantages of not warping, deforming or cracking. Since its establishment over 20 years ago, our company has achieved zero complaints in the building formwork industry, gained attention, and pursued excellence and perfection as our goals. We warmly welcome new and old customers, as well as domestic and foreign merchants, to visit our company and negotiate business

1. who are we

We are based in Guangxi, China, start from 2023, sell to Southeast Asia(30.00%), Domestic Market(30.00%), North America(20.00%), South America(10.00%), Mid East(10.00%). There are total about 5-10 people in our office.

2. how can we guarantee quality

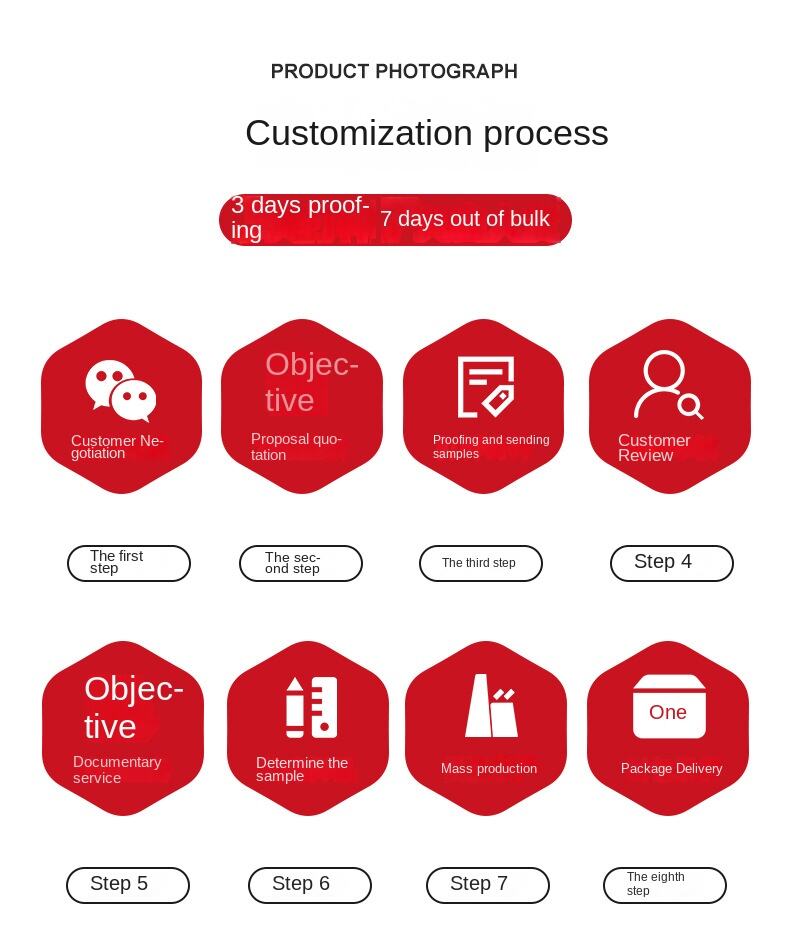

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3. what can you buy from us

Wood, Plywood, Film Faced Plywood, Construction Plywood, Bamboo Plywood

4. why should you buy from us not from other suppliers

Guangxi Dinghaode Wood Industry Co., Ltd. has its production base located in the Guiping Ecological Industrial Park, Guangxi. The company covers an area of 188 mu and has over 500 employees. It mainly produces construction wood formwork, laminated plywood

5. what services can we provide

Accepted Delivery Terms: FOB;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: -

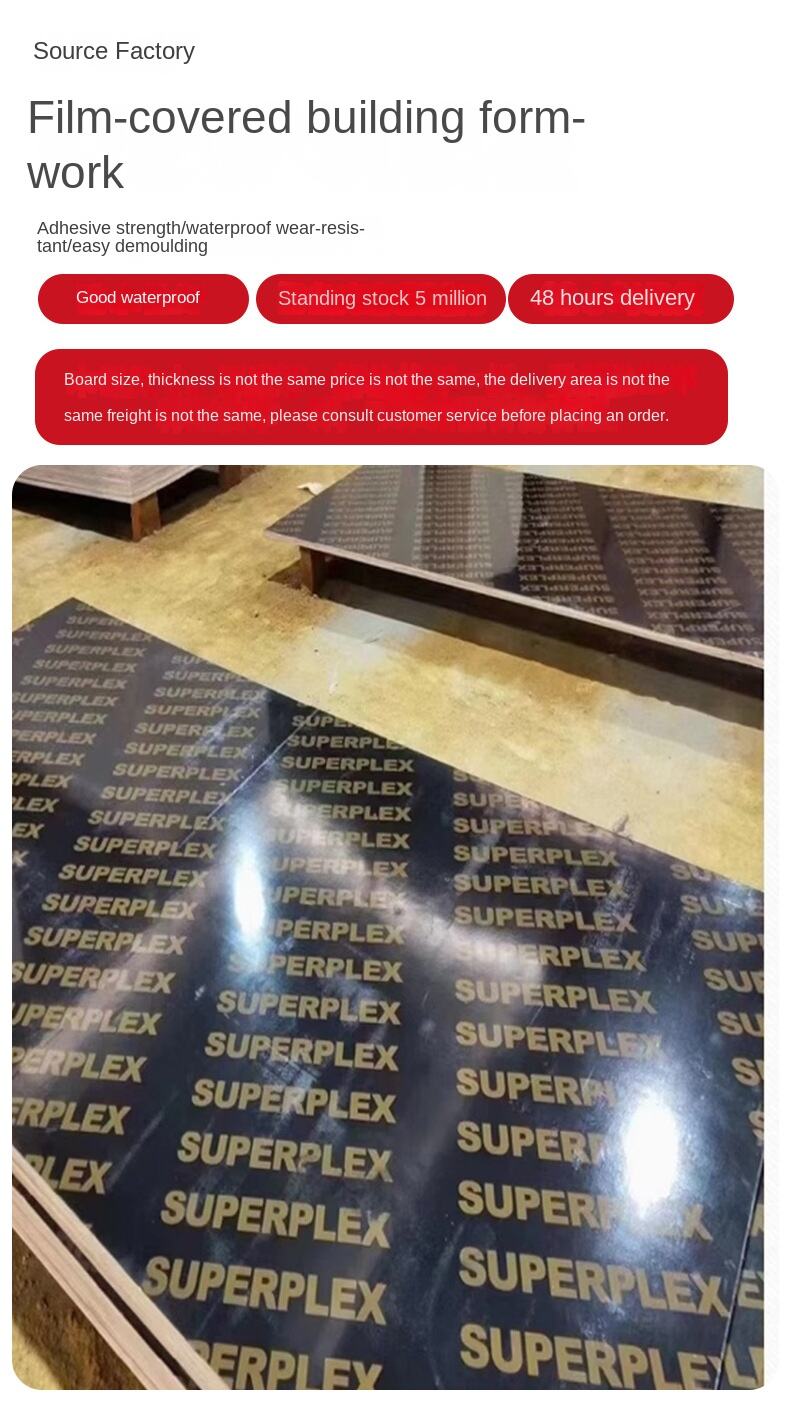

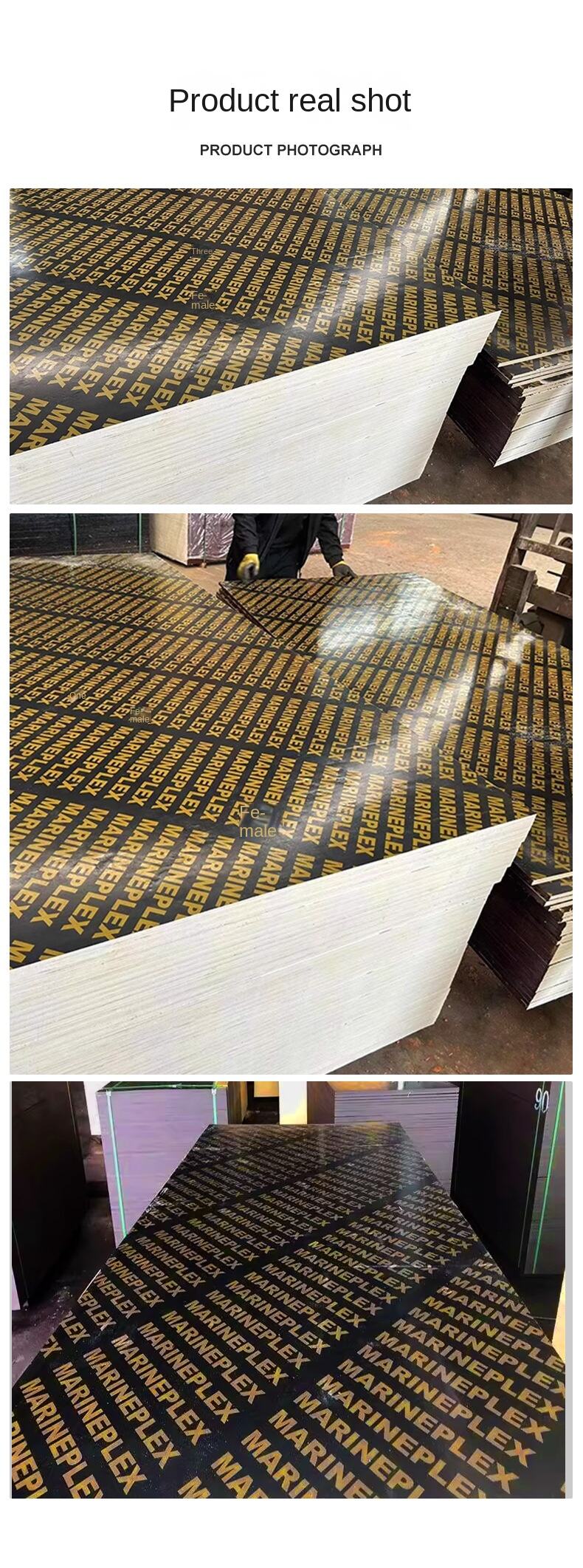

Black construction formwork, also known as film-coated formwork or fair-faced board, has a preliminary panel layout process similar to red boards, but its surface uses film-coating technology, with both sides covered with black or red film paper made from special adhesive. This film paper makes the surface of black construction formwork smoother and more even, and it can be used more times than construction red-face templates and phenolic mirror boards of the same thickness. The manufacturing process of black construction formwork is relatively complex, so its price is higher than the other two types of formwork. Its surface is a layer of black adhesive film paper, and if there are quality issues with the core board, they will be directly reflected on the surface, making it easy to inspect the quality of the formwork. Most black construction formwork has waterproof and anti-corrosion properties and can be used in relatively complex environments such as hydropower stations, dams, bridges, high-rise buildings, and subways. It is recommended to choose black film-coated construction formwork, as it performs better than red construction formwork.

Red and black construction formworks do not differ in functionality; they are both used as formwork for cast-in-place concrete structures in construction projects. The formwork structure mainly consists of three parts: panels, supporting structures, and connectors. The panels are in direct contact with the freshly poured concrete, the supporting structures bear the panels, concrete, and construction loads to ensure the stability and integrity of the formwork, and the connectors are components that connect the panels with the supporting structures to form a unified whole.

Construction formwork refers to the molds and supports used for pouring and shaping concrete. Based on the material properties, it can be divided into construction formwork, construction plywood, film-faced boards, multilayer boards, double-sided laminated boards, double-sided film-faced construction formwork, and so on. According to construction process conditions, construction formwork can also be classified into cast-in-place concrete formwork, pre-assembled formwork, large formwork, jump formwork, etc. As a new type of formwork, wood-plastic construction formwork has advantages such as light weight, high impact resistance, easy assembly, high turnover rate, smooth surface, non-absorbent, mold-resistant, acid and alkali resistance, crack resistance, large panel size, fewer joints, and the ability to be cut, nailed, or customized to any length.

In practical application, the lifespan of construction formwork depends on the usage conditions and maintenance. The lifespan of a single board may vary depending on factors like frequency of use, construction environment, and degree of maintenance. Generally, high-quality wood-plastic construction formwork can be reused multiple times, potentially more than 10 times. However, the specific number of uses should be determined based on actual conditions. Nevertheless, using high-quality, durable formwork can significantly reduce construction costs and improve work efficiency.

It is worth noting that although red and black construction formwork are functionally similar, they differ significantly in appearance and color. These color differences may affect the overall visual effect at the construction site but do not impact the performance of the formwork. Therefore, the choice of color should be based on project requirements and the designer’s preference.

In summary, red and black construction formwork are functionally identical; both are used as formwork for cast-in-place concrete structures in building support projects. In practical use, the lifespan of the formwork depends on usage and maintenance, while color differences primarily affect the overall visual appearance of the construction site.

Differences Between Black Formwork and Ordinary Formwork

1. Black formwork has significant advantages over ordinary construction formwork. It is lightweight, comes in large panels, does not warp, deform, or crack, has good water resistance, and a long service life. It is especially suitable for high-rise buildings and bridge construction. For fair-faced concrete, it produces smooth and aesthetically pleasing surfaces, eliminating the need for secondary wall plastering, allowing direct surface decoration.

2. Black formwork has strong corrosion resistance and will not stain the concrete surface. It can be processed into various shapes of formwork according to construction needs.

3. The various advantages of black formwork make it more suitable for construction compared to ordinary formwork:

(1) Ensures that its position, shape, and dimensions fully comply with the design requirements.

(2) Has sufficient load-bearing capacity and stability to withstand various loads encountered during construction.

(3) Simple structure, easy to install and dismantle, flexible to use. It can meet requirements for rebar tying, is suitable for centralized manufacturing, saves raw materials, improves efficiency, speeds up work, and meets the requirements of subsequent procedures.

Precautions for Storing Construction Formwork

1. When storing or transporting construction formwork, care must be taken to avoid impacts, scratches, or drops, as these can affect the product's functional quality.

2. When storing, the environmental conditions required for the product must be met. For stacking two pieces of the product, the boards should be placed facing each other. When stored at construction sites, certain anti-tilt measures should be taken, and they should not be placed leaning against walls.

3. If there is no supporting object during storage, a dedicated stacking rack should be used. The formwork should not be placed directly on other construction materials to prevent tipping over.

4. Construction formwork should not be stored in overly humid environments to avoid cracking or mold due to moisture. Additionally, transport personnel should not throw or drop the materials to prevent damage to the internal or surface quality of the product.