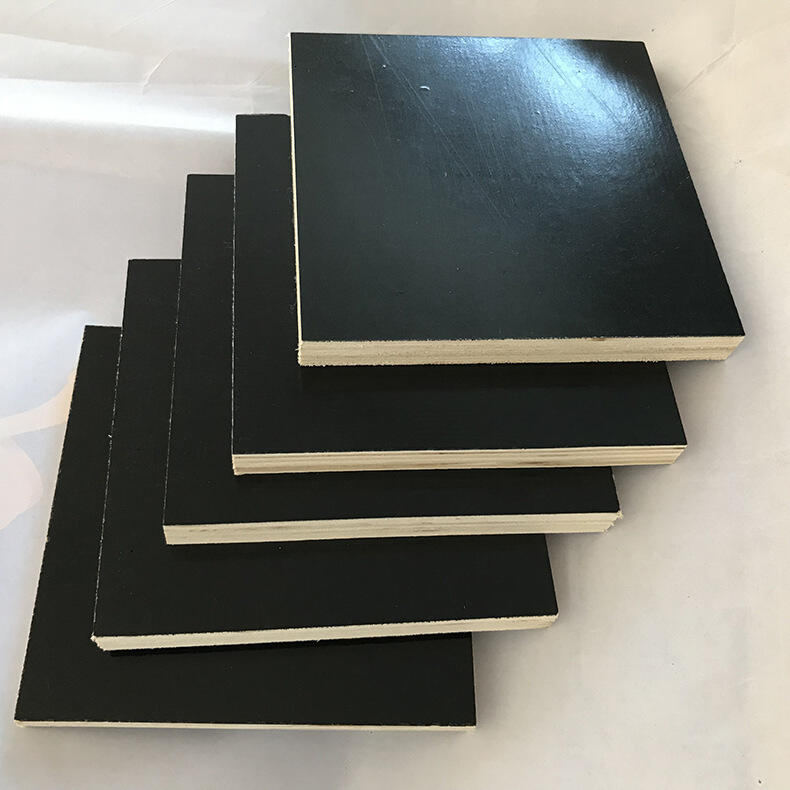

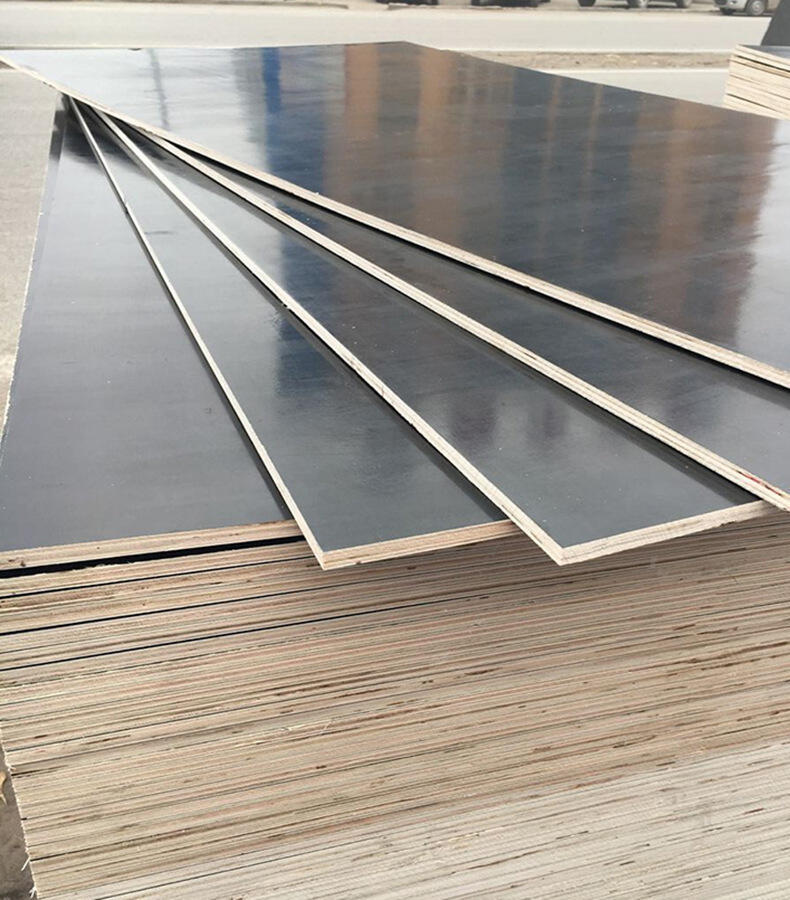

Introducing, Dinghaode’s Melamine 3mm Veneer Boards Film-Coated Building Formwork, a high-quality solution designed specifically for hotel construction and other demanding building projects. These boards are made to combine strength, durability, and safety, making them an excellent choice for construction needs where formwork plays a key role.

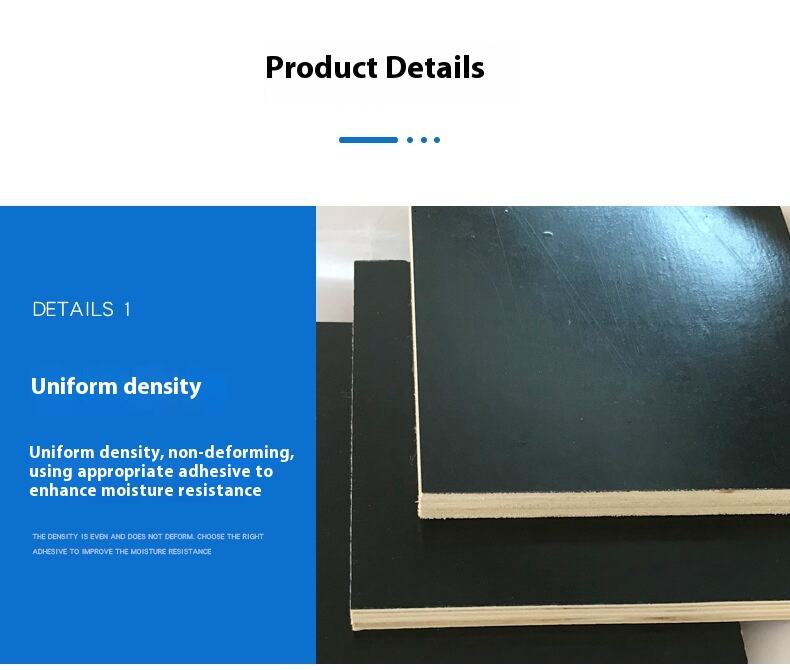

Dinghaode’s melamine veneer boards are coated with a special film that not only improves their appearance but also adds an important layer of protection. This coating makes the boards resistant to water, scratches, and wear, ensuring that they maintain their strong structure throughout the construction process. This feature is very useful in hotel construction where repeated use and exposure to different building materials can quickly wear down lesser-quality boards.

One of the most significant benefits of these 3mm melamine veneer boards is that they meet formaldehyde emission standards. Formaldehyde is a chemical sometimes found in building materials, but it can be harmful if released in large amounts. Dinghaode ensures that their panels are safe to use and environmentally friendly by keeping formaldehyde emissions low and within safe limits. This makes the boards a healthy option for both construction workers and the future occupants of the hotel.

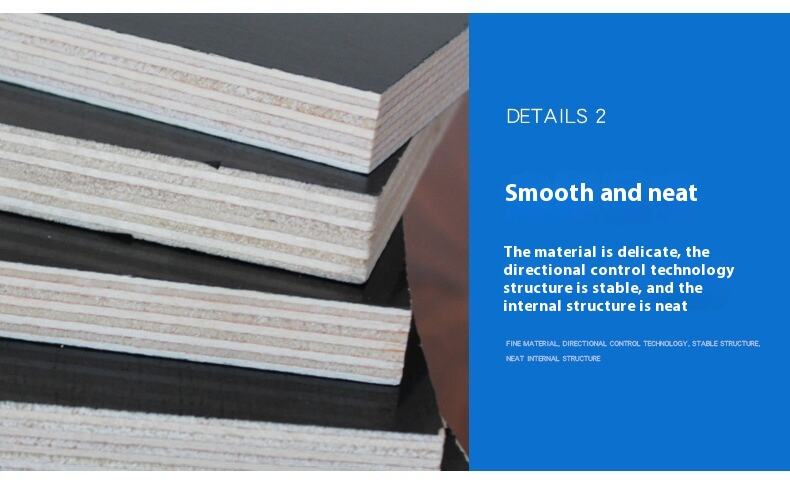

The thickness of 3mm provides an ideal balance between strength and ease of use. These boards are strong enough to hold up under pressure during the building formwork stage but light enough to handle and install without excessive effort. This helps speed up the construction process and reduce labor costs.

Additionally, the smooth surface of the film-coated veneer boards allows for easy cleaning and maintenance, which is essential on busy construction sites. It also results in a clean, neat look when the concrete is poured and forms the final structure. This smooth finish reduces the need for extra surface treatment or finishing work, saving time and money in the long run.

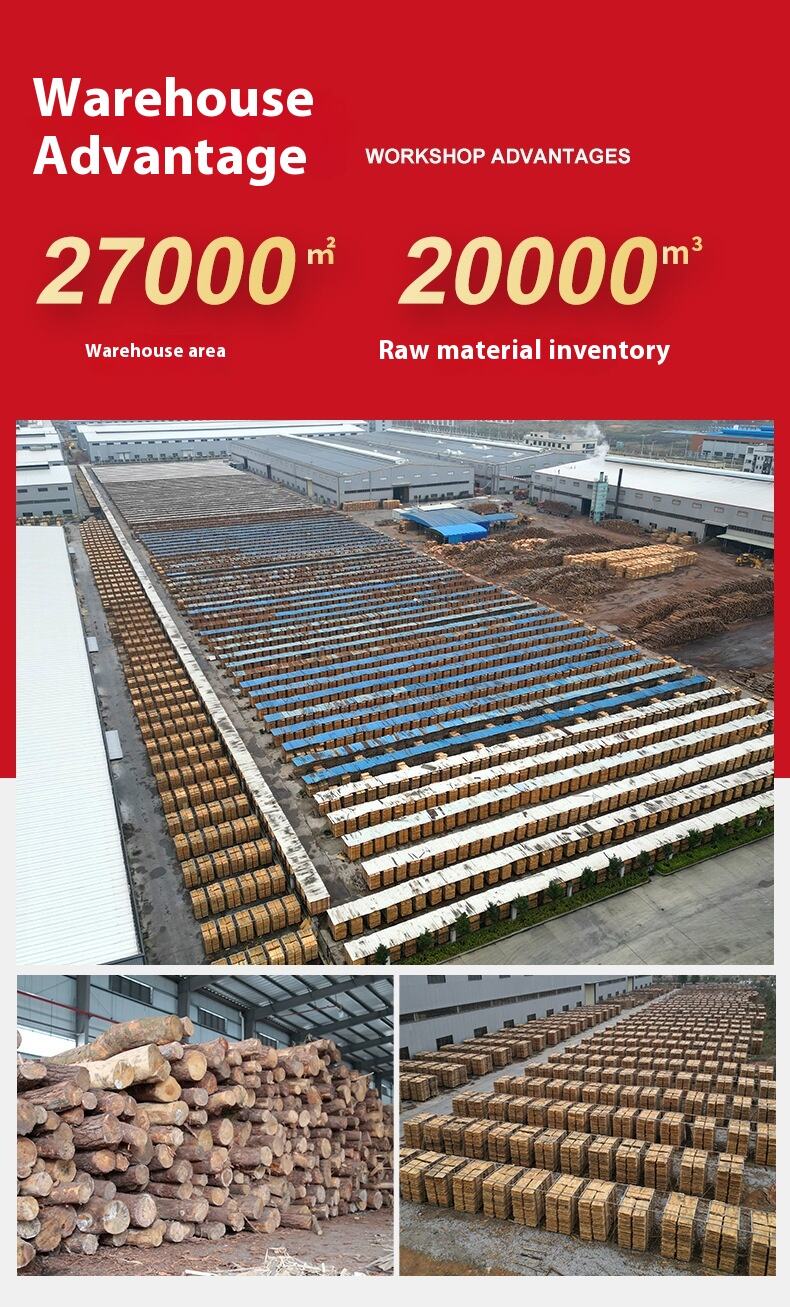

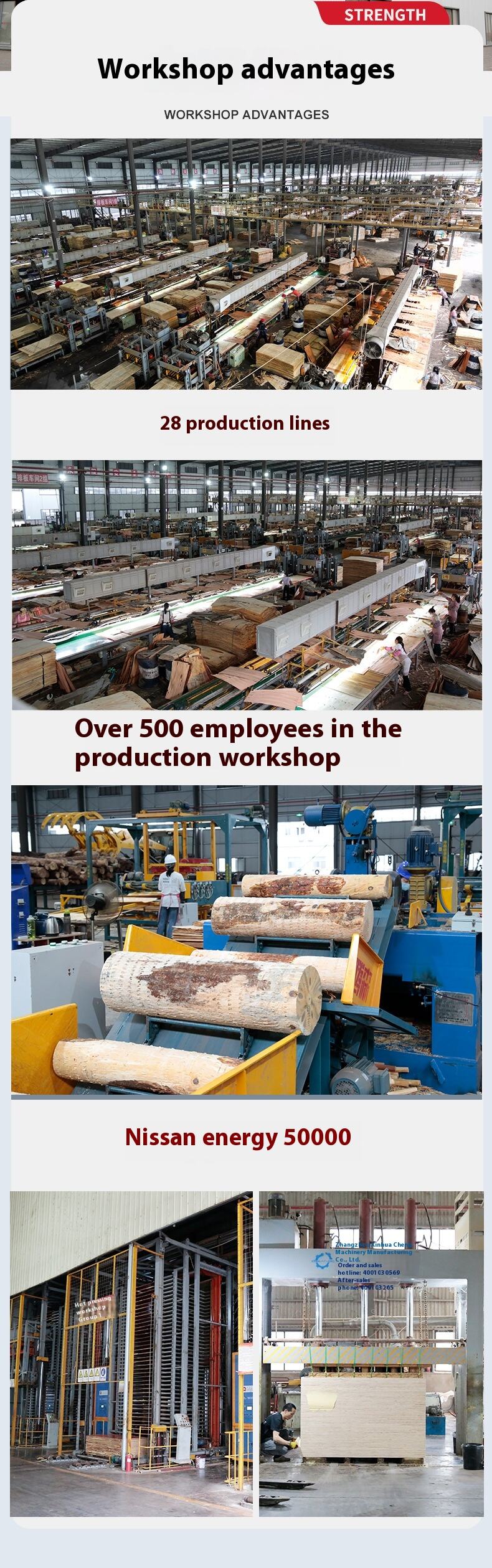

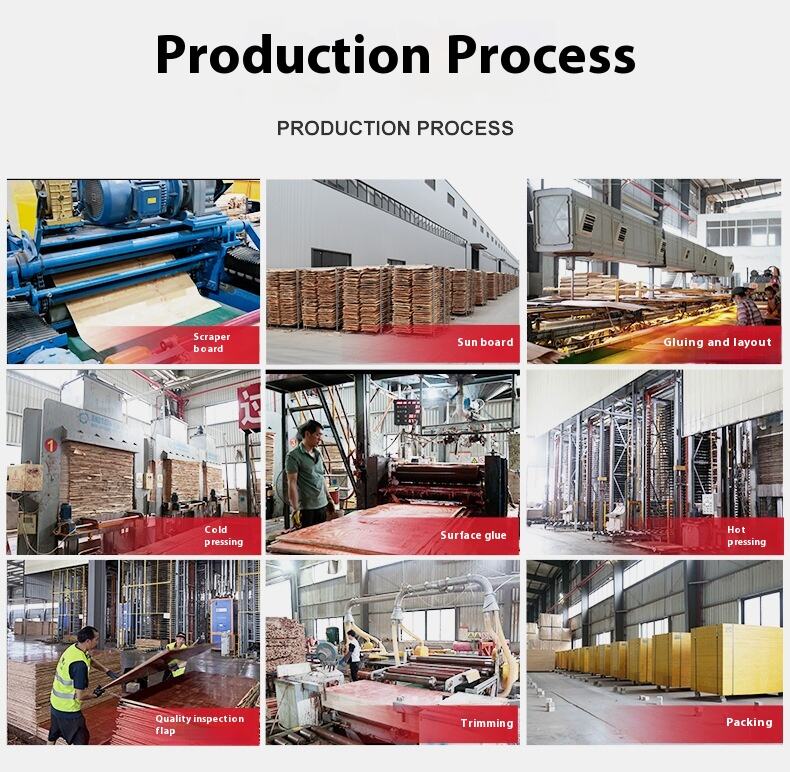

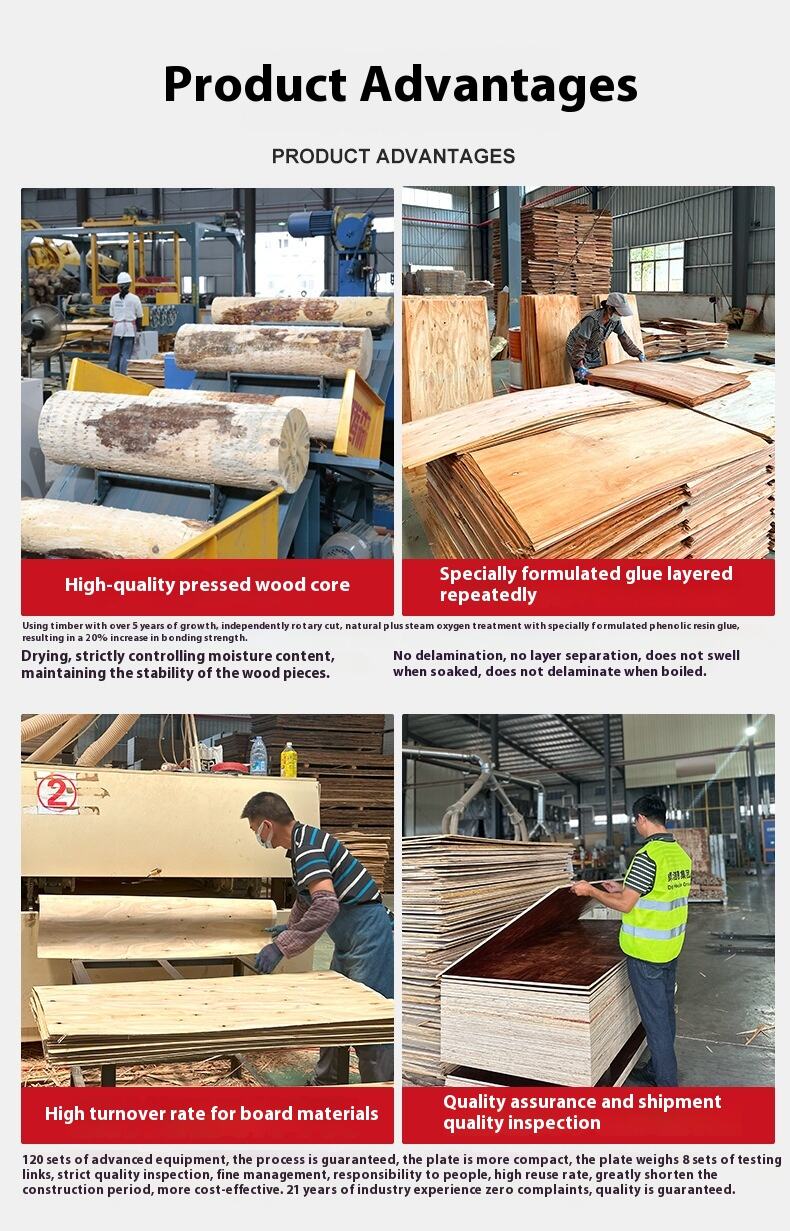

Dinghaode is known for its commitment to quality and customer satisfaction, and their melamine veneer boards are no exception. These panels are produced using high-quality wood materials and advanced manufacturing techniques, ensuring consistent performance and reliability.

Dinghaode’s Melamine 3mm Veneer Boards Film-Coated Building Formwork is a smart choice for hotel construction projects. They are strong, durable, safe, and easy to use. By choosing these boards, builders can expect efficient construction, safer working conditions, and a better end result for hotel buildings

x'xxxxx

x'xxxxx

| Project | value |

| Project solution capability | Overall project solution |

| Application | Construction formwork |

| After-sales service | Online technical support |

| Origin | China |

| Main materials | Eucalyptus/pine/poplar |

| Formaldehyde emission standard | E0 E1 |

| Guarantee | one years |

| Characteristics | Waterproof |

| Surface | Hot pressing |

| Design style | Industry |

| Surface veneer | Film surface |

| Brand | Dinghaode |

| Model | Z002 |

| With | Outdoor |

| Grade | First class |

| Surface treatment of single board | Double-sided decoration |

| Panel/single board grade | First class |

1. Question: What kind of wood do you use to make plywood

Answer: As our factory is located in southern China, we usually produce plywood cores using eucalyptus veneer or pine veneer. But we also produce plywood made of poplar and other woods

2. Q: I've noticed that many factories are using poplar veneer. What are the differences between poplar veneer and eucalyptus veneer

Answer: Eucalyptus veneer: Eucalyptus belongs to the category of hardwoods. Eucalyptus trees are widely planted in tropical and subtropical regions. It is hard in texture, with high density and strength, and has excellent wear resistance and corrosion resistance. Due to its hardness and durability, it is usually relatively expensive

Poplar veneer: Poplar belongs to the category of softwood. Poplar trees are mainly distributed in northern China. It is soft in texture, low in density, light in weight, and easy to process and carve. It has a soft texture, a short growth cycle and a relatively low price.

3. Q: Is the reuse frequency of eucalyptus formwork higher than that of poplar formwork

Answer: Generally speaking, for eucalyptus formwork of the same thickness, poplar formwork can be used 2 to 5 times or more depending on its thickness

4. Q: How long will it take for my order to be produced

Answer: Generally, after we confirm the order, the production process takes 7 to 15 days. Depending on your country or region, it will still take 15 to 50 days for the goods to arrive in your country or region

5. Q: Can I request a sample before making a decision

Yes, we don't charge for samples. You only need to pay the shipping fee to us. After the order is confirmed, the fee will be deducted from the total payment