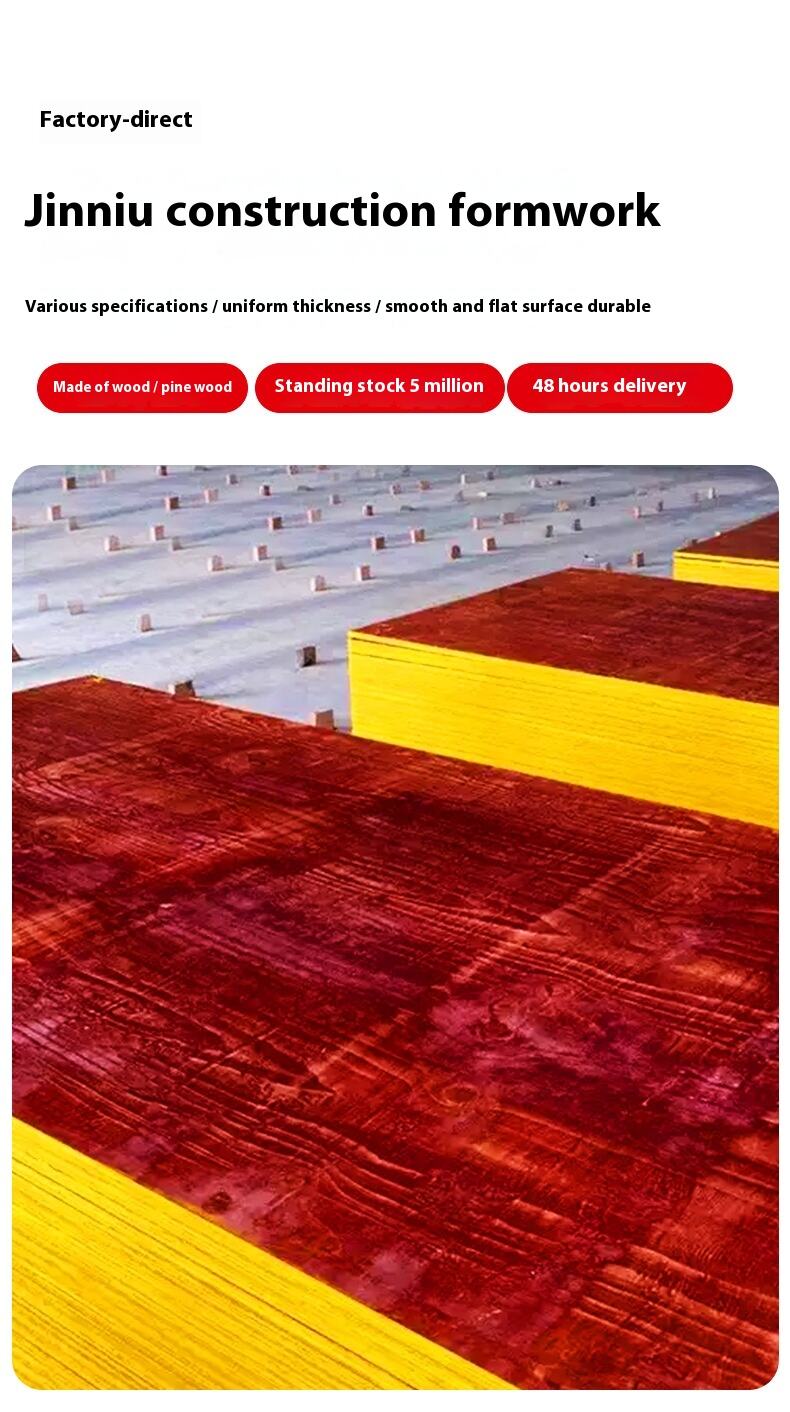

The Dinghaode Wholesale Stock 2440*1220mm Construction Site Plywood is a reliable and high-quality building material designed to meet the needs of various construction projects, especially high-rise buildings. This special building red board template plywood is known for its strength, durability, and versatility, making it a popular choice among builders and contractors.

Measuring 2440mm by 1220mm, each plywood sheet offers a large, consistent surface that is ideal for creating strong and stable structures. The size is standard for many construction applications, which makes handling, cutting, and installation easier and more efficient on busy job sites. Dinghaode’s plywood sheets are made with precision to ensure uniform thickness and smooth surfaces, which helps provide excellent support and a neat finish for any construction project.

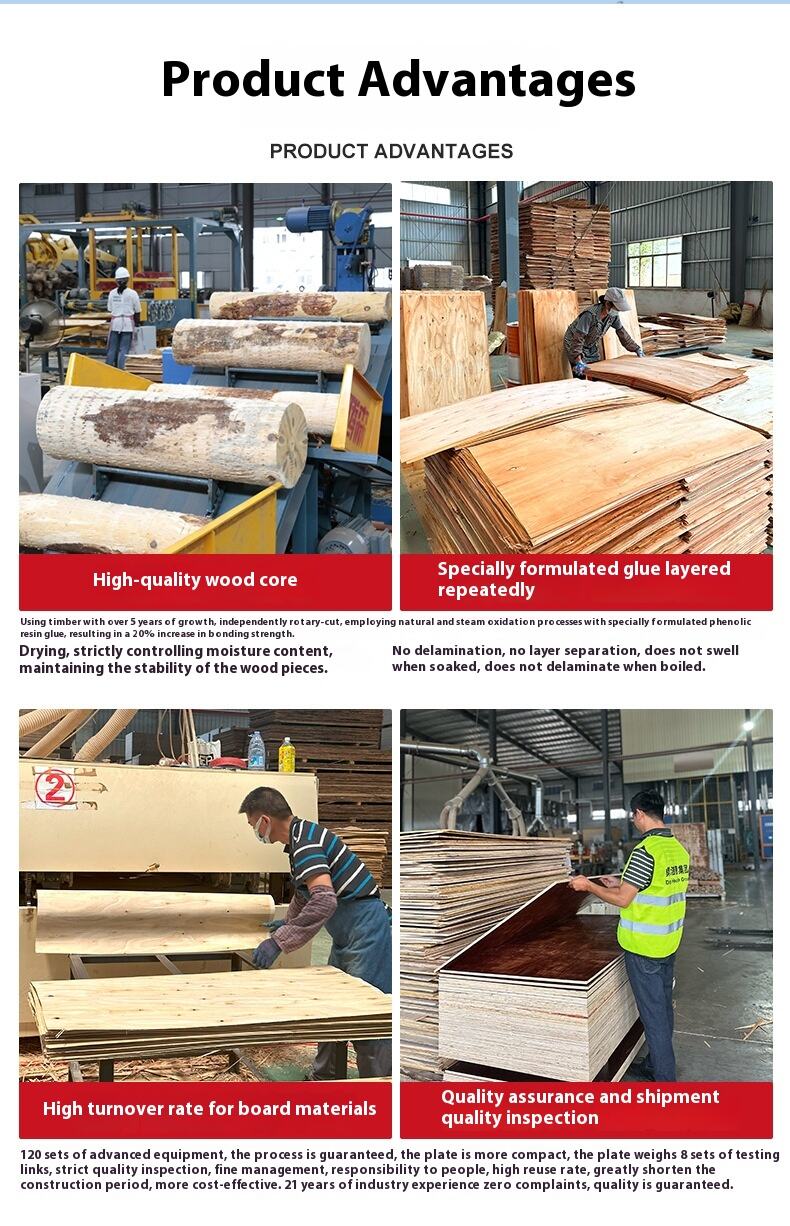

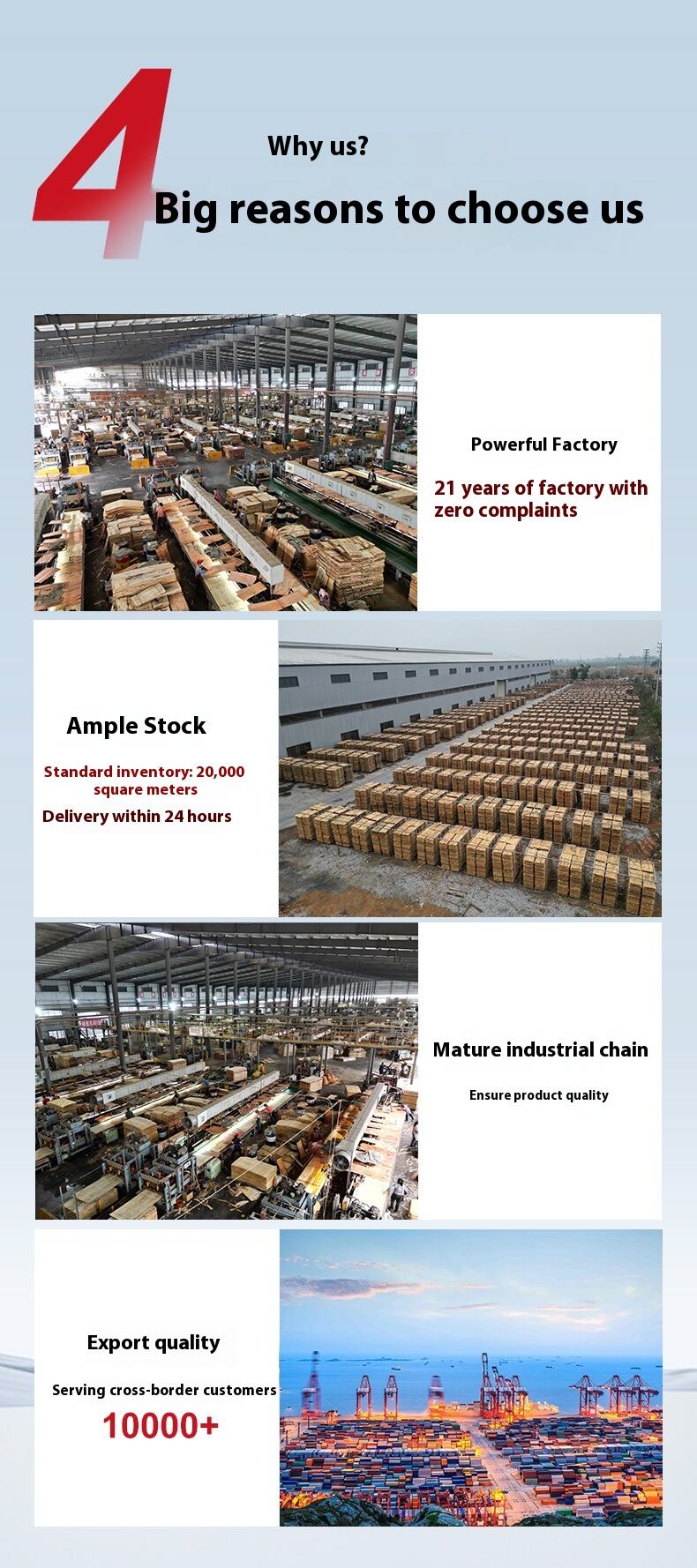

One of the key features of this plywood is its high turnover rate, meaning it is frequently used and trusted due to its superior performance and competitive price. This makes it a cost-effective option for large-scale projects where materials need to be purchased in bulk. Builders appreciate the quick availability and steady supply of Dinghaode’s plywood, reducing downtime and keeping construction schedules on track.

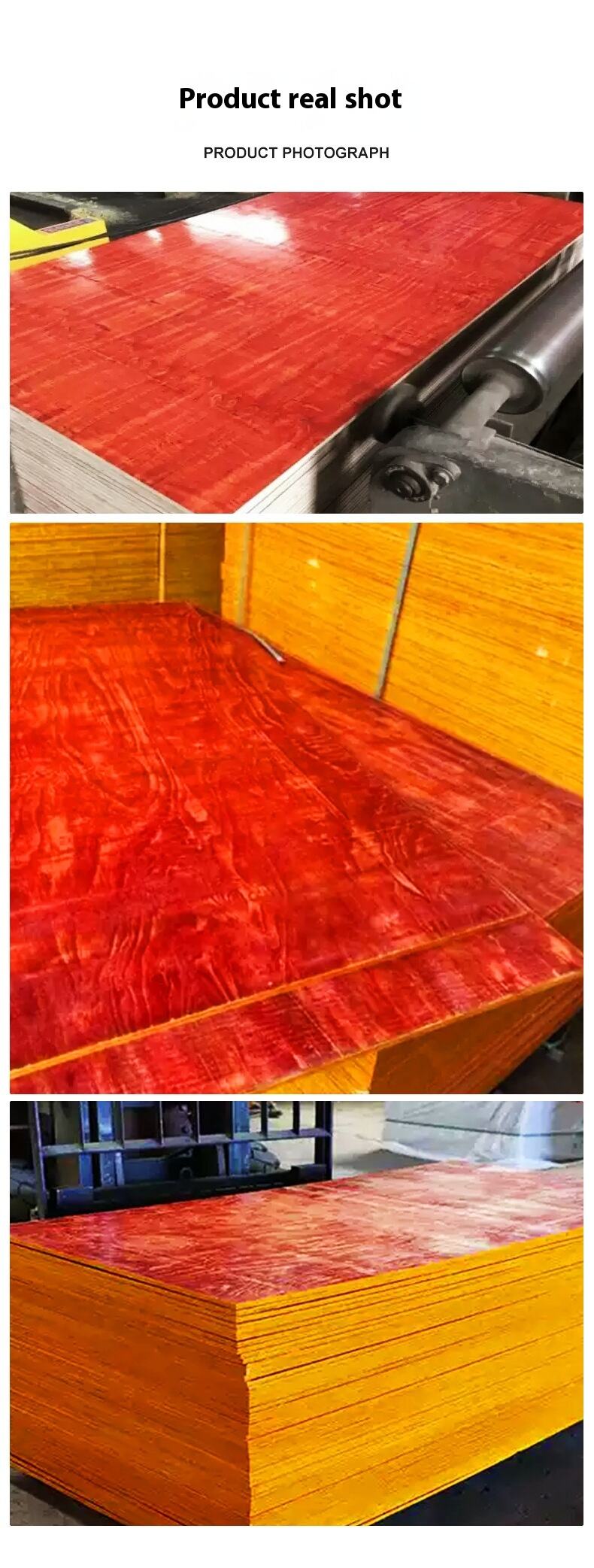

The special red board template design indicates its suitability as a formwork panel for concrete work. This plywood is specially treated to resist moisture, preventing warping and deterioration during use. Its coated surface ensures easy cleaning and multiple reuse cycles, which saves money and resources over time. It provides a smooth finish to poured concrete and is strong enough to hold heavy loads, making it perfect for high-rise buildings, bridges, and other demanding construction structures.

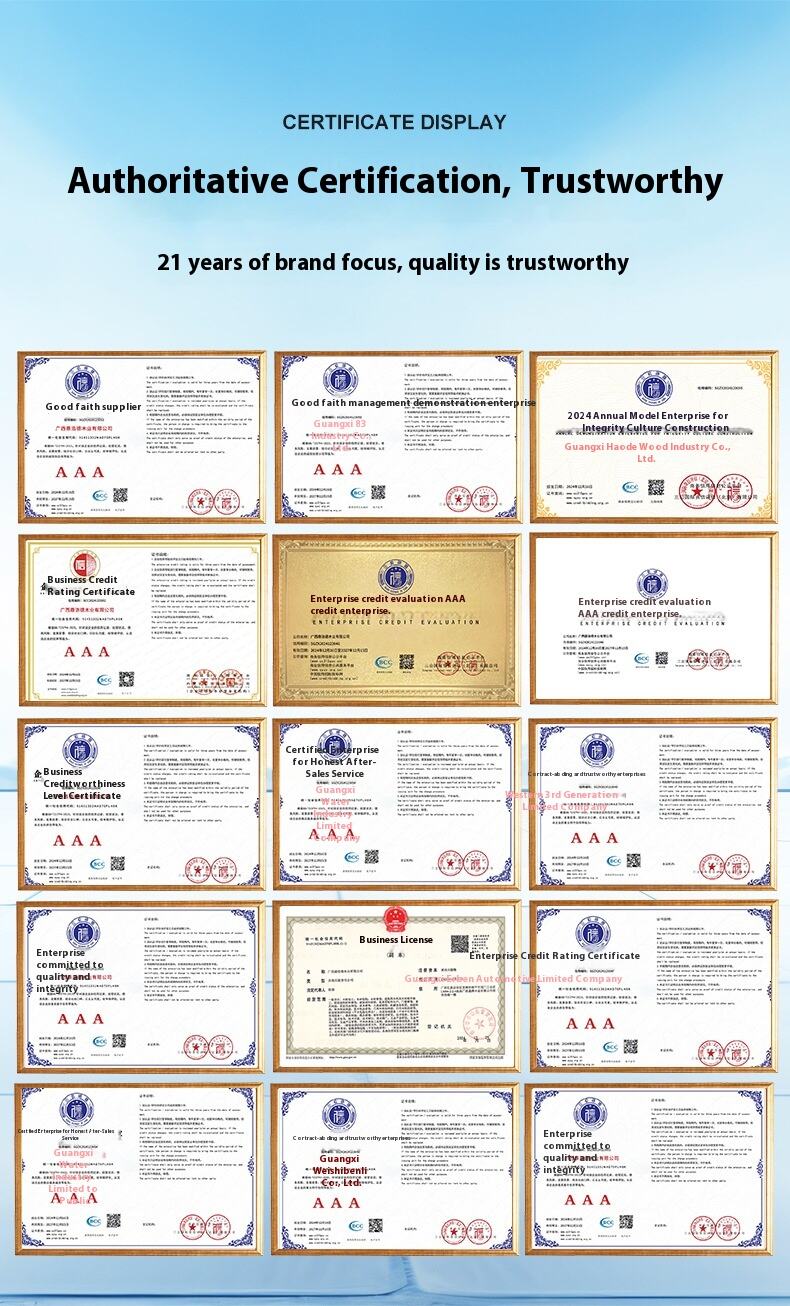

Dinghaode is a trusted brand in the construction industry, known for producing durable and high-performance plywood products. Choosing Dinghaode plywood guarantees that you are using materials that comply with industry standards and offer reliable support throughout your construction process.

The Dinghaode Wholesale Stock 2440*1220mm Construction Site Plywood is the ideal choice for contractors and builders looking for strong, reusable, and cost-effective plywood. Its special red board design is perfect for high-rise buildings and other concrete formwork applications, making it a smart investment for any serious construction project

| Project | value |

| Project solution capability | Overall project solution |

| Application | Construction formwork |

| After-sales service | Online technical support |

| Origin | China |

| Main materials | Eucalyptus/pine |

| Formaldehyde emission standard | E0 |

| Guarantee | Two years |

| Characteristics | Waterproof |

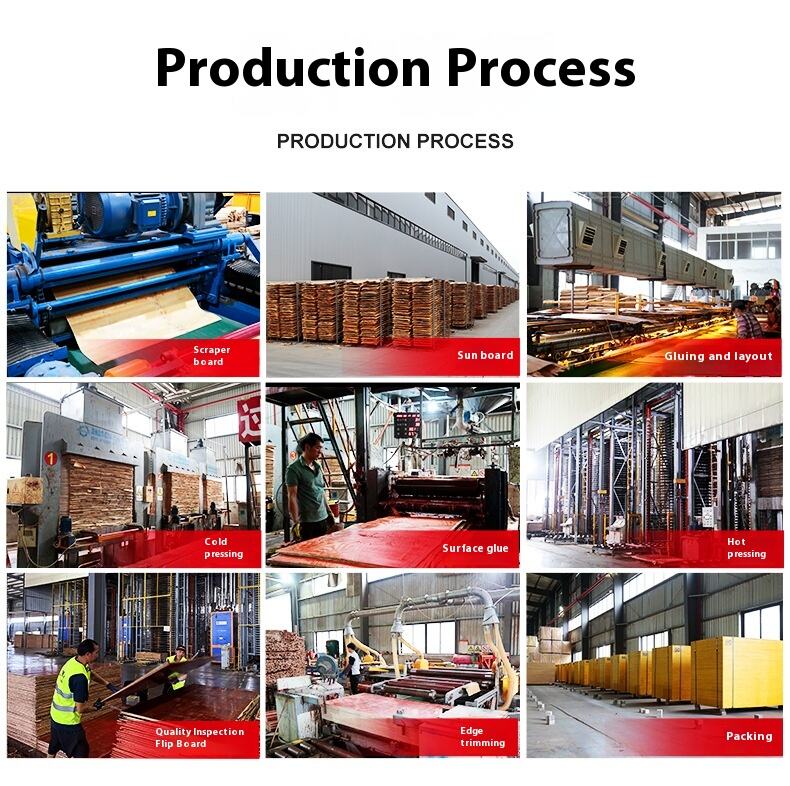

| Surface | Hot pressing |

| Design style | Industry |

| Surface veneer | Film surface |

| Brand | Dinghaode |

| Model | Z002 |

| with | Outdoor |

| Grade | First class |

| Surface treatment of single board | Double-sided decoration |

| Panel/single board grade | First class |

1. Question: What kind of wood do you use to make plywood

Answer: As our factory is located in southern China, we usually produce plywood cores using eucalyptus veneer or pine veneer. But we also produce plywood made of poplar and other woods

2. Q: I've noticed that many factories are using poplar veneer. What are the differences between poplar veneer and eucalyptus veneer

Answer: Eucalyptus veneer: Eucalyptus belongs to the category of hardwoods. Eucalyptus trees are widely planted in tropical and subtropical regions. It is hard in texture, with high density and strength, and has excellent wear resistance and corrosion resistance. Due to its hardness and durability, it is usually relatively expensive

Poplar veneer: Poplar belongs to the category of softwood. Poplar trees are mainly distributed in northern China. It is soft in texture, low in density, light in weight, and easy to process and carve. It has a soft texture, a short growth cycle and a relatively low price.

3. Q: Is the reuse frequency of eucalyptus formwork higher than that of poplar formwork

Answer: Generally speaking, for eucalyptus formwork of the same thickness, poplar formwork can be used 2 to 5 times or more depending on its thickness

4. Q: How long will it take for my order to be produced

Answer: Generally, after we confirm the order, the production process takes 7 to 15 days. Depending on your country or region, it will still take 15 to 50 days for the goods to arrive in your country or region

5. Q: Can I request a sample before making a decision

Yes, we don't charge for samples. You only need to pay the shipping fee to us. After the order is confirmed, the fee will be deducted from the total payment

Red construction formwork, also known as red-faced construction formwork or phenolic mirror construction formwork, is a type of formwork with multiple advantages. Its surface is coated with melamine waterproof adhesive, giving it a red color, while the core of the board is made from various wood materials such as poplar, pine, or eucalyptus, making the formwork itself relatively lightweight and easy to use. Red formwork is processed using the hot-pressed plywood method, generally with a thickness of 1.2-1.6 cm, suitable for typical concrete projects such as house construction and the ground floors of buildings. As an upgraded product of red construction formwork, phenolic mirror formwork offers more advanced features. It uses higher-grade phenolic glue, providing better waterproofing and a smoother surface, making demolding easier. Its number of uses is similar to that of red-faced construction formwork, but compared to black formwork, the number of uses is generally 2-3 times fewer.

1. Similarities between red and black construction formwork :

Both red and black construction formwork are supporting structures in construction, and they serve the same purpose. The construction formwork used in cast-in-place concrete projects mainly consists of three parts: panels, supporting structures, and connectors.

(1) The panel is the load-bearing board that directly contacts the newly poured concrete.

(2) The supporting structure is a temporary structure that supports the panel, concrete, and construction loads, ensuring that the construction formwork is firmly assembled without deformation or damage.

(3) The connectors are used to join the panels and supporting structures into a unified whole.

2. Differences between red and black construction formwork:

(1) The most obvious difference is the color: one is red, and the other is black, making them easy to distinguish. Black construction formwork is also called film-faced board.

(2) Red is usually painted with pigment, while black is coated with enamel-like paint. There is a significant price difference; comparatively, black formwork is slightly better. In practice, the black formwork has a glossy surface in contact with concrete, while the red one is rough. Selection depends on quality requirements.

(3) In terms of performance, with equal quality, the red board can be used 2–3 times less than the film-faced board. In terms of pricing, red boards of the same quality are 1 yuan per square meter cheaper than film-faced boards. In practice, the usage rate of both types is still nearly the same. Both types are typically sized 2440mm x 1220mm and 1830mm x 915mm, with the 1830mm x 915mm size being more commonly used.

Precautions for Storing Construction Formwork

1. When storing or transporting construction formwork, care must be taken to avoid impacts, scratches, or drops, as these can affect the product's functional quality.

2. When storing, the environmental conditions required for the product must be met. For stacking two pieces of the product, the boards should be placed facing each other. When stored at construction sites, certain anti-tilt measures should be taken, and they should not be placed leaning against walls.

3. If there is no supporting object during storage, a dedicated stacking rack should be used. The formwork should not be placed directly on other construction materials to prevent tipping over.

4. Construction formwork should not be stored in overly humid environments to avoid cracking or mold due to moisture. Additionally, transport personnel should not throw or drop the materials to prevent damage to the internal or surface quality of the product.