Concrete is hard substance commonly found in building materials, such as houses, bridges and roads. To give form and to keep concrete where it belongs as it hardens, builders rely on plywood forms. This is constructed from thin sheets of wood, called plywood, and put together to form a cast. After concrete is poured into these molds, it conforms to the mold’s form and sets. Ply shuttering is common because it’s not difficult to work with and yields smooth surfaces. At Dinghaode, we produce high-grade ply shuttering products that makes the builders job easy.

1.3 Advantages of WBP ply shuttering There are many advantages of using WBP ply in construction(e.g., easily angled bendable, strong etc). First, it is lightweight. Sheets are also portable around construction sites for builders to maneuver easily. It thus becomes easier to install and remove the molds. Second, ply shuttering is strong enough to bear the weight of heavy concrete while it hardens. That means it can be used for larger projects, such as bridges and tall buildings. Third, the use of ply shuttering leads to excellent even surfaces. Good and neat when dry. That saves time and money in that you’ll have to do less expending of extra effort after the fact. For instance, our 1220x2440mm Multi-layer Interlocking Waterproof Plywood (PP Material) Used for Formaldehyde Waterproof Formwork Bridge is an excellent choice for such applications.

The use of ply shuttering also aids to the pace with which construction can be completed. Easy installation allows workmen to pour the concrete faster while allowing them to move on to other steps of construction. This can help complete projects early. Here’s Therest at Dinghaode, we specialize in manufacturing robust ply shuttering that is exactly what builders need and want to accomplish their projects on time and within budget.

You could also try going online. Many of these companies — including Dinghaode — have websites listing their products. You can price compare and search for the best deals online. You will also be able to check the reviews of other customers and buy shuttering which is of good quality. Also make sure the company delivers, because especially with heavy materials, that can save you lots of time and energy.

Finally, don’t forget to search for discounts or promos. You’ll find that some companies run modest seasonal sales or promotions, which can save you even more money. By browsing smart and considering your options, you can obtain the best ply shuttering for your construction projects at prices that are affordable. At Dinghaode, we are committed to offering builders the best materials and prices to assist them in their project.

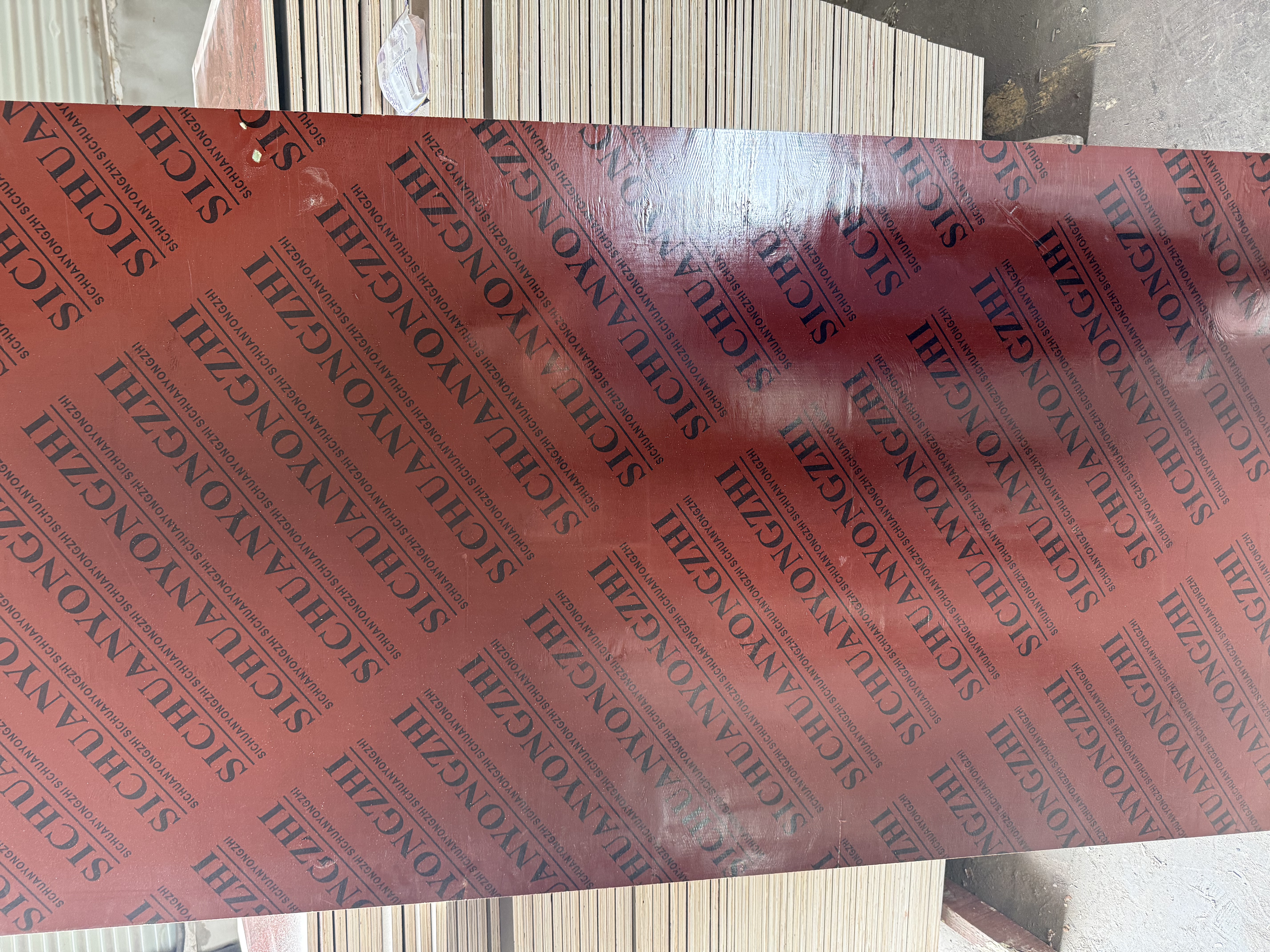

Ply shuttering concrete is an integral part of a strong and safe structure. When we describe the extent of durability or stability, we are referring to how long a building will last and whether it will stand up well. Concrete is made stronger when ply shuttering is used. It is also known as plywood shuttering, and this material is particularly strong and able to hold a substantial weight. It is the ply shuttering used to make molds into which workers can pour concrete; this enables the concrete to hold its shape while drying. That’s important, because good shape is what the building will be in if it isn’t falling apart. Comes equipped with High quality ply shuttering that is instrumental in constructing safe homes, schools and other construction. The plywood shields the concrete from bad weather, such as rain or wind, while it remains wet. This protection ensures that the concrete cures properly, allowing it to grow even more durable over the years. Strong buildings are great, because they can withstand heavy winds or earthquakes; and they keep the weight of everything inside from collapsing on our heads. That means using ply shuttering isn’t just about making buildings last longer: It’s also a way to keep everyone inside them safe. Through making the right material choice, such as Dinghaode, builders can construct buildings that last. For instance, our Wholesale Modern Construction Site Plywood Red Board Template 2440x1220mm Moisture-proof Outdoor Use High Turnover Rate offers excellent durability.

Installing ply shuttering concreteIt is crucial to install ply shuttering properly in order to get the best results. First, workers must ready the site of the building. This involves ensuring the ground is level and ready to build on. Then they will need to opt for high grade ply shuttering from a reliable brand such as Dinghaode. The plywood must be free of dirt and damage. Wet or broken wood, for example, can result in trouble when it comes time to pour the concrete. After completion of the ply shuttering, forms or molds will be constructed by the workers. They have to ensure these are strong and well-packed so the concrete doesn’t seep out. Then it is time to add the concrete. Workers should be careful to pour it slowly and evenly, without air pockets that can weaken the material. Newly poured concrete needs to be levelled and left to dry. During this time, it is crucial to keep the concrete wet so that it cures properly. This is accomplished by placing an object over the pile, then wetting it down with burlap or plastic. Lastly, when the concrete has fully dried, remove the ply shuttering. The correct use of ply shuttering concrete can have a significant impact on the strength and durability of a building for many years to come.