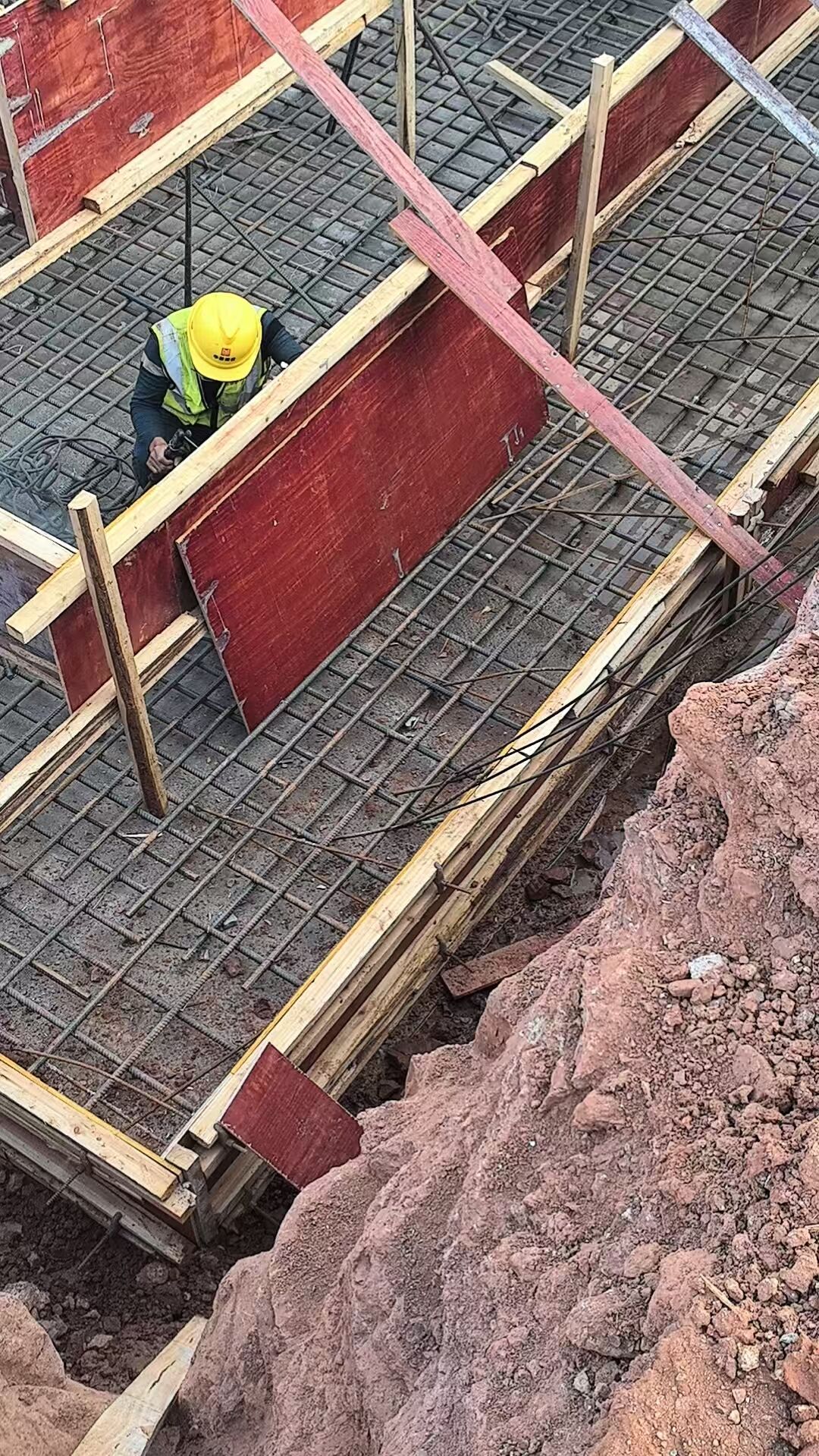

Construction materials include all necessary products to build something solid. They are a mold in which concrete is cast. When construction workers pour concrete, they require an object to keep the it in place until it sets. Formwork is usually made from wood, metal, or plastic. All of them have their own advantages. Dinghaode has set its focus on producing high quality formwork materials to guarantee building builders a safe and strong building. The right formwork not only saves time and money in construction, but also makes for easier construction.

Selecting the right formwork plywood material is a key decision on any construction project. The type of structure to be constructed is the first thing to consider. Different buildings have different needs. For instance, if the project involves a high-rise building, metal formwork could be the best selection. Metal is tough and can withstand heavy loads. It’s also more durable than some of the alternative materials, which makes it a great investment for large projects.

Good quality wholesale formwork systems can be extremely useful for builders and workers in the construction industry. Formwork is a temporary structure that supports concrete until it dries and it is strong enough. To locate good formwork, many people begin by searching the internet. Online marketplaces like Dinghaode offer different types of formwork materials at wholesale prices, so they are less expensive when purchased in large numbers. You may want to consider other types of formwork, such as wood, metal or plastic. There are pros and cons to each, depending on the project you’re doing.

Local construction supply stores may also have wholesale formwork. These formwork sheets shops also usually have experienced employees that can assist you in selecting the right materials for your project. They might also offer specific deals or discounts for bulk purchases. Be sure to ask your local timber store workers for advice, or any questions you may have since they can offer up some valuable information on the formwork that’s best suited to your project.

There are times when formwork construction will have issues, and these problems can hinder the build process. One of the most common problems that can arise is not using the correct formwork for a project. For instance, if the project requires heavy-duty formwork but lighter materials are employed, the structure could collapse. This black formwork plywood can be avoided if the appropriate type of formwork is selected depending on the concrete quantity and strength required. Educational resources are available from companies such as Dinghaode, which can inform on the best materials for specific projects.

Finally, the best way to avoid mistakes is for the construction crew to communicate. Everyone should be clear on what is expected of them, and regular check-ins can help identify any problems early. Construction companies adhere to the principle that construction is a formwork plywood sheets and can only be completed successfully with teamwork. This way you can avoid common problems that formwork construction may present, in order to have a smooth and safe construction.

Today, there are numerous new and exciting developments in form work materials. One of the most trends is the use of lightweight materials. Traditional construction plywood formwork is often heavy and difficult for workers to handle. New, lightweight options like plastic and aluminum can be simpler to transport and assemble. Not only are they lighter, but strong, holding the concrete in place. Offering these new materials is paving the way for companies like to provide construction that's easier and safer.