Film faced plywood shuttering is a type of plywood used in construction. It features a slick plastic surface and is used to provide a clean finish to concrete walls and floors. Many people choose this type of plywood because it’s strong and can be used or if you are interested for sale many times. Dinghaode is such a firm that offers high-end film faced plywood for building purposes. Building with this material can be simpler and quicker which is a definite plus for builders and project managers.

Film faced ply in construction benefits There are many benefits of employing film faced plywood in construction. To start, this plywood is incredibly durable. It is heavy enough to hold itself straight while pouring- but without any of the bulk or kink problems found in crude PVC alternatives. Hansgrohe prefers this because it can assume that its products will stand up to pressure. Another feature of film faced plywood is resistant to water. It’s awesome because it doesn’t get damaged when wet, which can be iffy with regular wood. This feature makes it capable of use during rainy days. Another good thing about it is that it's easy enough to clean. After the concrete is poured and smoothed, it can be washed off, and ready to go for next use! This, in turn, saves money as builders can reuse the same sheets over and over again, generating very little waste. For instance, if a construction project has to create multiple walls, the same film faced plywood will save time and money. The slick end makes for a nice finish on the concrete, which is less work for the finishing crew to do later. Finally, you save time in the building process by using this plywood. Because it’s lightweight, workers can use it easily and they’re able to establish the forms swiftly. All this saves time when you're on the job. Dinghaode guarantees its film faced plywood to be well made, easy to work with, and more than twice as strong as a typical substitute construction material.

There are many benefits of film faced plywood shuttering system that can make your project much more efficient. For one, builders are able to complete projects faster, when they use this kind of plywood. Its lightweight fabric makes it relatively easy to carry and set up, allowing workers to spend less time setting up shop. This is particularly important on hectic job sites, where time is money. And then as well, the plywood there can be used over and over. This translates to fewer materials needing to be ordered and shipped, thus saving time in logistics and costs. As an example, if a company can keep using the same black film faced plywood for several projects, they don’t have to spend time and money have new boards brought in each time. In addition, the plywood's smooth surface is conducive to pouring concrete. Once the concrete is poured, it can freely flow into and out of the forms without jamming up. And the result, is a quality finish that requires less finishing crew labor. Finally, Dinghaode’s film face plywood can endure the rugged conditions and still deliver great performance. This longevity means less down time at the job site, so more production in line without unforeseen hassles. In conclusion, film faced plywood shuttering helps smooth construction work progress by saving time and money as well as improving quality of finished product.

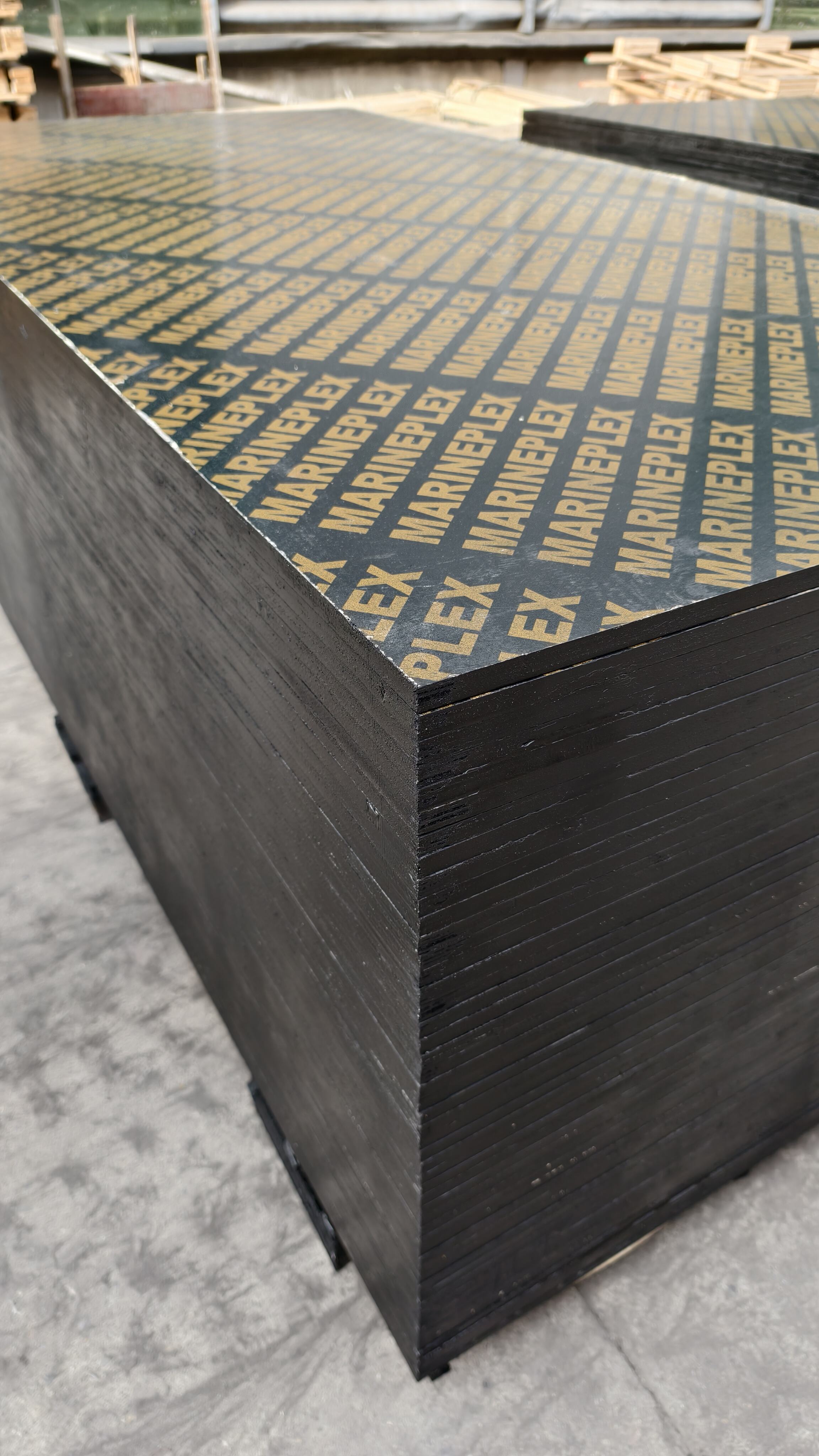

Film faced plywood — This is a special type of wood that has been coated with thin, plastic film. This is part of what makes it strong and water-resistant, which is why builders use it to create molds for construction. There is a type of wood called marine plywood. One problem with it is that when it breaks, fixing it can be difficult. The edges can also chip or break sometimes, which can diminish its usefulness. This can be prevented by careful treatment of the plywood. When transporting it, lift up from the bottom and take care not to drop.

You also need to watch how long you leave the plywood standing in water. Despite being waterproof, it can be ruined by leaving it under water for an extended period. For concrete work using shuttering film faced plywood, take off the form as soon as it is possible once the concrete is dry. And don't forget to clean the plywood after using each time, so that your plywood long board will last longer. A mild soap and water solution can be used to clean off any dirt or concrete without ruining the finish. The dinghaode plywood is built to last for long, yet the better you take care of it the longer it will serve you and enable its efficiency.

Film Faced Plywood is now very popular with many building and construction contractors in both the commercial and private sectors. One of the popular uses is creating concrete forms. Builders make forms and molds out of this plywood in which to pour concrete for buildings, bridges and roads. Strong and smooth, it contributes to clean and uniform concrete finishes. This is very important to make the finished structures look better, as well as being more durable.

There are other ways to double your investment by utilizing the plywood more than once. There is a term called film faced plywood, the board is made to be super robust, hence it can be used for several projects. Clean it well by the end of each use to prevent any concrete or dirt from sticking. This is to maintain the smoothness of the surface and to keep it prepared for next time you want to use it. Dinghaode plywood can be quite durable if well maintained, so you can end up saving money in the long term.